|

|

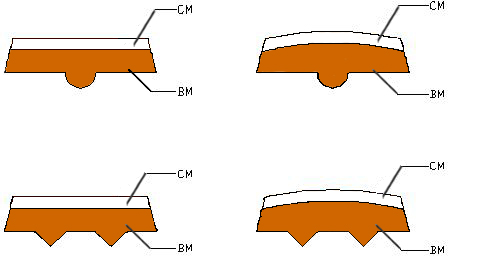

Heterotypic compound contact belt

1.Heterotypic junction zoneA strip electrical contact material used for making electrical contacts of electrical components. According to the actual performance requirements, the cross sections are designed into specific shapes, such as triangles, trapezoid and other complex shapes (as shown in Figure 1). 2.Heterotypic junction belt The heterotypic contact zone is rolled by a single noble metal, precious metal alloy or evenly distributed noble metal powder metallurgy material, with a special shape of strip electric contact material. 3.Heterotypic compound contact zone The special-shaped compound contact zone is composed of single or multilayer precious metals and their alloys, noble metal powder metallurgy materials and other metal materials, which are composed of rolling, welding, electroplating and gas phase deposition, with a special shape of strip electric contact material.

Product material:

Surface material: gold, gold and silver alloy, pure silver, silver nickel, silver and copper, silver oxide cadmium, silver tin oxide, etc.Middle level: pure silver, silver nickel, red copper, brass, zinc white copper, etc. Base material: nickel, iron, stainless steel, Monel and so on;

Specification type:

Triangle, trapezium or other specialties, specific specifications can be customized according to customer requirements.

Product application:

It is mainly used in electrical, information, communication and national defense technology industries, such as communication relay, micro switch, key, temperature control device, circuit breaker and connector, and so on.

Product advantages:

1. The comprehensive characteristics of a single metal;2、Save precious metals; 3、Meet the needs of automated production; 4、The interlayer bonding strength is high, surface finish, dimensional stability and consistency are high, thereby improving the electrical life and reliability;

For example, figure 1:

rhombus contact of plum blossom:

The diamond contact of the plum blossom is made of three layers of metal, in which the working surface materials are silver, fine silver, silver nickel, silver oxide, silver oxide indium, silver copper, silver Zinc Oxide, silver oxide and so on. The welding surface materials are CuNi, Fe and so on, such as fine crystal silver / copper / iron, silver nickel / copper / iron, silver oxide tin / copper / iron, etc. The welding surface is a cold rolled low carbon steel or copper nickel alloy with good welding performance, with 5-7 plum blossom points or diamond points to ensure the soldering of the contact and the double metal sheet. It is widely used in micro switches, thermostat, keystroke and breaker protectors.

Product features:

①The three layer compound electric plum blossom diamond contact surface is pure iron and has small convex point to increase the welding performance, and it can make the electric contact soldering firmly with the iron base alloy, such as the double metal sheet and the stainless steel sheet.②Welding position is through fused metal joint, its electrical stability is better than riveting contact contact and good positioning and beautiful welding. If riveting method is used, riveting is too tight to make double metal deformation, riveting is too loose and the system resistance increases, which will cause the error of the temperature control device. ③Compared with the brazed contact, the heating time is short and the working environment is clean. It is suitable for jointing of micro parts, especially for the use of micro mechanism. For the three metal compound contact, different silver alloy materials can be selected according to the electric current passed by the electric appliance. It is suitable for the pulse welding method and the contact bridge connection, and can prepare the electrical contact parts and the double metal touch bridge. It is widely used in the relay, micro switch, temperature controller, key, temperature controller and circuit breaker. |