|

|

Silver alloy wire - tape - contact

Electrical contact application of silver alloy wire - belt - contact mainly include: pure silver, fine crystal silver, silver, nickel, palladium silver copper, silver copper, silver tin oxide, silver tin oxide indium oxide, silver zinc oxide, silver cadmium oxide, etc. Series of products.

Product material:

1.Sintering extrusion process, the density can be up to 99.9%, while the silver base in the second set of RMB become a fibrous, fibre arrangement direction perpendicular to the electric contact product surface, improve the material fusion welding resistance, arc resistance loss and mechanical wear resistance ability.2. 80/5000 Silver tin oxide, silver tin oxide, indium oxide, silver copper, silver, nickel, silver adding trace elements such as zinc oxide wires, achieve the effect of dispersion strengthening, improve mechanical strength material products, to improve the material physical and mechanical properties and resistance to the burning of the arc performance is greatly increased; 3. By chemical coating method, coprecipitation method, mechanical alloying and pre oxidation process, the material of grain refinement, organize uniform doesn't appear segregation, microstructure, eliminate oxide lean ridge area, create materials with excellent properties.

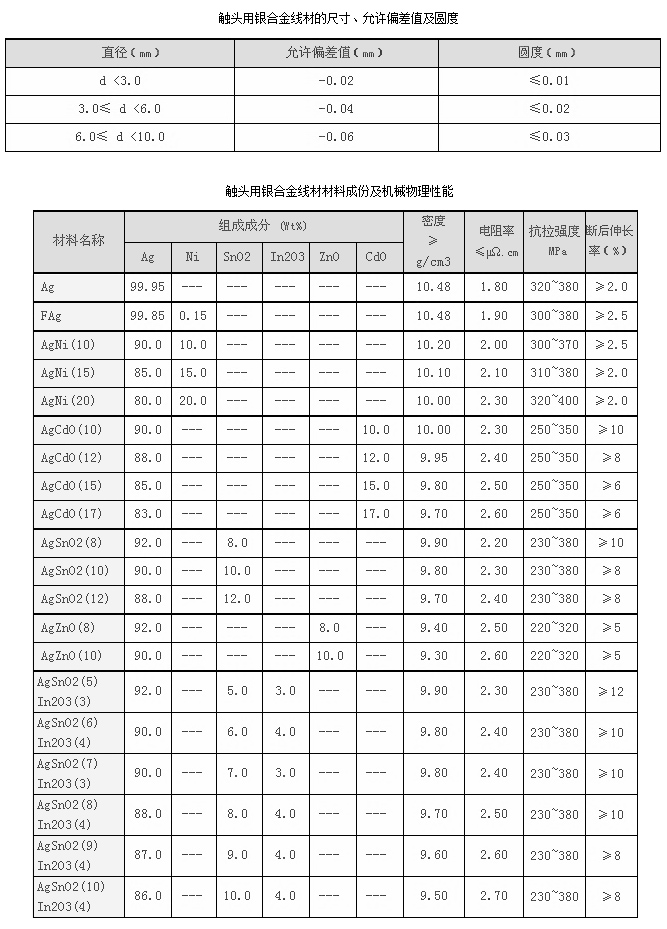

Specifications types:

Wire: wire diameter of 0.2~6.0mm;Strip: thickness of 0.05~3.5mm, width of 1.5~80mm.

Product application:

Silver alloy wire - belt - contact contacts, relay, starter, voltage controller, ac/dc power relays, automotive electrical appliances in the low-voltage dc contactor, and used to power protection switch, leakage protection switch, relay communication, DZ15L series leakage circuit breakers, etc., some large capacity switch also use silver zinc oxide materials, such as the ME universal circuit breaker.

Specification parameter:

|